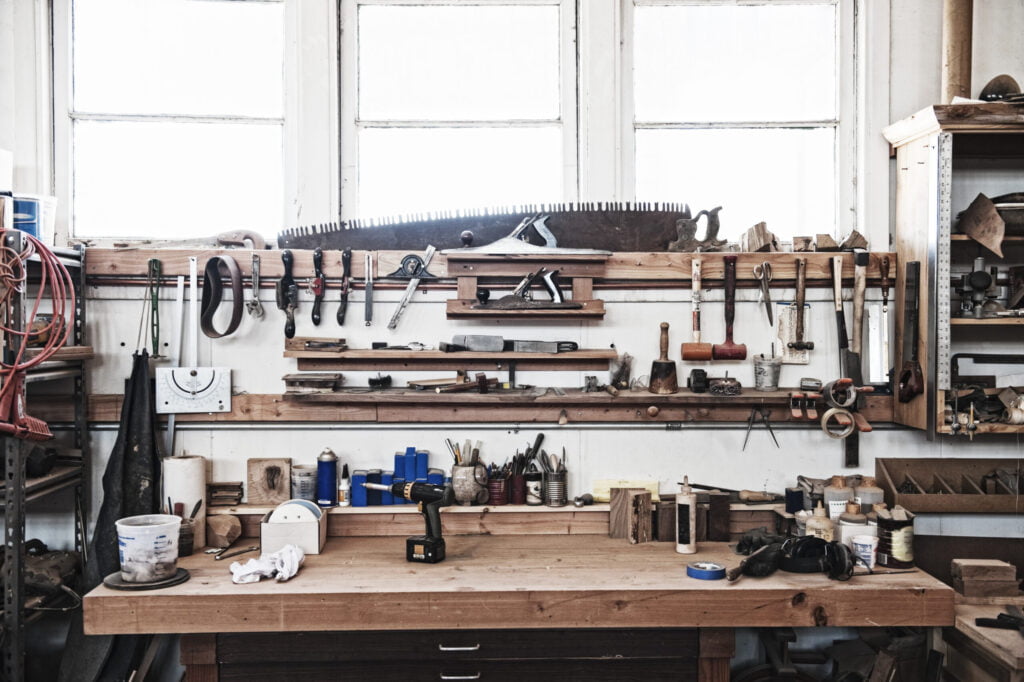

Tips and Techniques for Working With a Self-Adjusting Jig for Woodworking

Embarking on any woodworking project requires precision, skill, and the right tools. Among these tools, jigs are critical in ensuring consistent accuracy throughout various tasks. A self-adjusting jig, in particular, can dramatically streamline the process, easily accommodating different material thicknesses. This woodworking technology innovation helps craftspersons achieve professional-grade results regardless of their experience level. Below are insights and best practices to elevate your work with a self-adjusting jig for woodworking.

Understanding the Basics of Self-Adjusting Jigs in Woodworking

Self-adjusting jigs are remarkable tools that have changed the game for woodworkers. By design, these jigs automatically calibrate to the material’s thickness, saving time and minimizing errors. This adaptability ensures a snuggly fit for joinery, a factor paramount in creating sturdy furniture and wood structures. Grasping the basic mechanics and functions of self-adjusting jigs is the first step toward incorporating them effectively into your work routine.

The versatility of self-adjusting jigs lies in their ability to cater to a wide range of projects. Whether working on intricate inlays or robust cabinetry, these tools can readily adjust. A thorough understanding of the jig’s components, such as the clamping mechanism and the drilling guide, is essential. Knowing each part’s role enriches the user’s ability to troubleshoot and get the most out of these sophisticated tools.

For newcomers to woodworking, the aspect of self-adjustment can seem intimidating. However, today’s jigs come with comprehensive manuals and are generally user-friendly. Many tools now boast an intuitive design that eases the learning curve, enabling hobbyists to confidently approach projects. A solid grasp of your jig’s peculiarities will pay dividends in both the short and long term.

It’s important to note that while these jigs are designed for ease of use, mastery comes with practice. Starting with smaller, less complex projects allows woodworkers to become comfortable with the adjustments and settings. Over time, as familiarity grows, so too will the complexity of the projects they can tackle with confidence.

Essential Preparation Steps Before Using Self-Adjusting Jigs

Before diving into the actual work, preparation is key. Ensuring that the jig is securely fastened to the workbench prevents mishaps and inaccuracies during operation. Double-check the jig’s settings and ensure they align with the specific requirements of your project. This groundwork lays the foundation for a successful and seamless woodworking experience.

Material preparation is just as critical. Wood surfaces should be smooth and clean to allow the jig to make precise contact. Any debris or roughness can lead to maladjustment, impacting the final product.

Additionally, familiarize yourself with the safety features of your jig and adhere to standard woodworking safety protocols. Protective gear, such as goggles and earplugs, should be readily available and utilized throughout the process. Woodworking is an enjoyable craft, but it should never compromise personal safety.

Mastering the Adjustment Mechanisms of Self-Adjusting Jigs

The sophistication of self-adjusting jigs lies within their intricate adjustment mechanisms. It’s essential to become adept at controlling these to leverage the tool’s full potential. Detailed instructions usually accompany the jig, offering guidance on how to fine-tune these adjustments. Taking the time to understand and practice these adjustments will ensure the creation of tight, seamless joints.

It’s beneficial to develop a systematic approach when working on specific adjustments. For instance, identifying the exact point of contact where the jig meets the material and understanding how varying pressure affects the outcome can result in consistently better joinery. Repeating the process multiple times with attention to subtle differences refines one’s technique over time.

While self-adjusting, these jigs still allow for manual tweaks; these nuanced adjustments allow the woodworker to cater to specific woodworking challenges. Over time, developing a keen sense of when and how to execute these adjustments can become second nature, resulting in a harmonious interaction with the tool.

Overall, self-adjusting jigs represents a leap forward in woodworking technology, offering ease of use and extraordinary precision. When used correctly, these tools are not mere accessories but vital companions in the journey of craftsmanship.