The Function of Fermentation

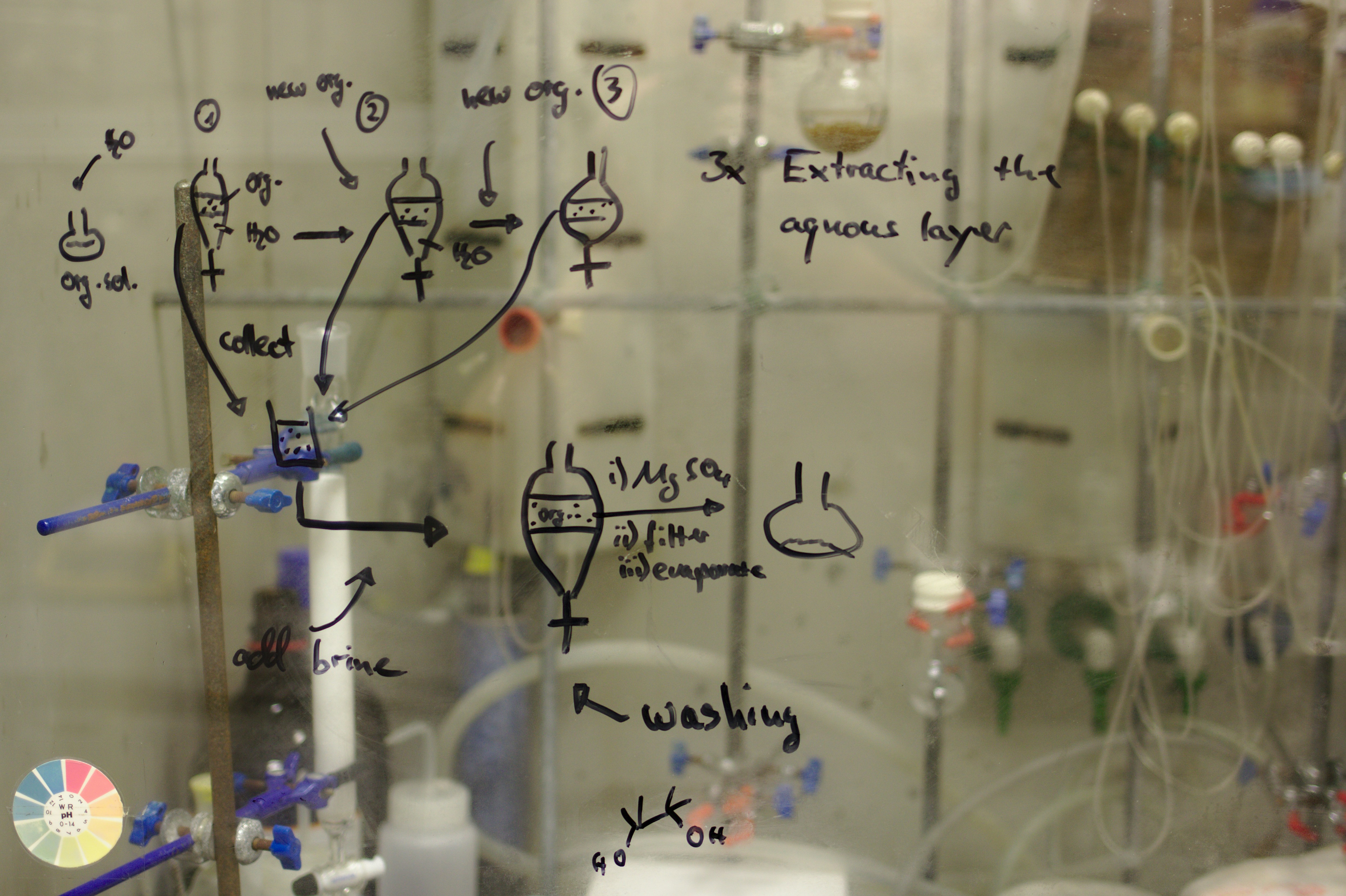

The study of fermentation and its practical uses stems from its discovery by French chemist Louis Pasteur, who demonstrated that fermentation was caused by yeast. Fermentation occurs in certain types of microorganisms that require an oxygen-free environment to live, and also in muscle cells when oxygen is in short supply. The processes of fermentation are valuable to the food and beverage industries, with the conversion of sugars into ethanol used to produce alcoholic beverages, the release of CO2 by yeast used in the leavening of bread, and with the production of organic acids to preserve vegetables and dairy products. The main function of fermentation is to convert NADH, a chemical compound found in all living cells, back into the coenzyme NAD+ so that it can be used again. This process, known as glycolysis, breaks down glucose from enzymes, releasing energy.Types of fermentation

During fermentation, an organic electron acceptor reacts with NADH to form NAD+, generating products such as carbon dioxide and ethanol (ethanol fermentation) or lactate (lactic acid fermentation) in the process.Ethanol fermentation

In ethanol fermentation, the pyruvate, or metabolic intermediary, produced through glycolysis is converted to ethanol and carbon dioxide in two steps. First, it releases carbon dioxide to form a two-carbon compound called acetaldehyde. Next, acetaldehyde is reduced by NADH to ethanol, thereby regenerating the NAD+ for use in glycolysis. Ethanol fermentation is typically performed by yeast.Lactic acid fermentation

There are two main types of lactic acid fermentation: homolactic and heterolactic. In homolactic acid fermentation, NADH reduces pyruvate directly to form lactate. This process does not release gas. In heterolactic fermentation, some lactate is further metabolized, resulting in ethanol and carbon dioxide via pathway. Lactic acid fermentation is primarily performed by certain types of bacteria and fungi. However, this type of fermentation also occurs in muscle cells to produce ATP when the oxygen supply has been depleted during strenuous exercise.

Recent Advances in Fermentation Research

Since launching in 1962, Bio-Technical Resources has offered cost-effective fermentation development services. A proven expertise in fermentation development and the fermentation process help make Bio-Technical Resources a world leader in providing R&D services for fermentation process development to different sectors of the biotech industry. Each process development program is unique and varies depending upon the starting point, the objectives, and the degree of difficulty in achieving the objectives. Some are long-term development programs, requiring years for completion. Others can be completed within several months. BTR tailors each program to fit our client’s goals and objectives.Some of the accomplishments of BTR in fermentation development:

- Increasing the fermentation yield of a therapeutic protein while identifying a mutation and correcting the gene sequence

- Leading the technology transfer of a generic antibiotic process, doubling the yield through process development

- Increasing the yield of an enzyme by 600% and assisting in identifying new market opportunities

- Conducting a complete technical and economic assessment of an enzyme transformation to develop time frames and work schedules for commercialization

energy, acid, lactic acid fermentation, bacteria, cell, nicotinamide adenine dinucleotide, carbon dioxide, metabolism, chemical reaction, oxygen, fermentation, cellular respiration, pyruvic acid, microorganism, ethanol, glycolysis, lactic acid, function of fermentation, enzyme, yeast, glucose, redox, ethanol fermentation, molecule, electron transport chain, fermentation in food processing, carbohydrate, metabolic pathway, alcoholic beverage, carbon, yogurt, electron, biology, nutrition, biochemistry, milk, taste, oxide, acetic acid, bread, organism, strain, citric acid cycle, industrial fermentation, vitamin, skeletal muscle, nutrient, acetaldehyde, product, lactic acid bacteria, digestion, organic compound, amino acid, hydrogen, saccharomyces cerevisiae, research, phosphorylation, electron acceptor, fatty acid, lactobacillus, chemical compound, substrate, contamination, sugar, citric acid, muscle, cereal, dairy, biotechnology, tempeh, probiotic, biosynthesis, methane, gene, catalysis, oxidative phosphorylation, prokaryote, vinegar, lipid, transport, disease, fungus, raw material, saccharomyces, soybean, starch, eukaryote, evolution, butyric acid, species, dehydrogenase, sauerkraut, archaea, meat, genetics, cell membrane, organic acid, lactose, louis pasteur, experiment, engine, mitochondrion, antibiotic, solution, genetic engineering, technology, cattle, fat, soil, juice, natural environment, yeast fermentation, propionic acid, biofuel, biodiversity, microbiology, food industry, atp synthase, innovation, antioxidant, blood, phosphate, crossref, nucleotide, bioprocess, diet, agriculture, hypoxia, lactate dehydrogenase, open access, shelf life, clostridium, aerobic fermentation, proteolysis, copyright, immune system, mdpi, waste, liver, carbohydrate metabolism, catabolism, cholesterol, hydrolysis, gut microbiota, concentration